English|Русский

|Site map

English|Русский

|Site map

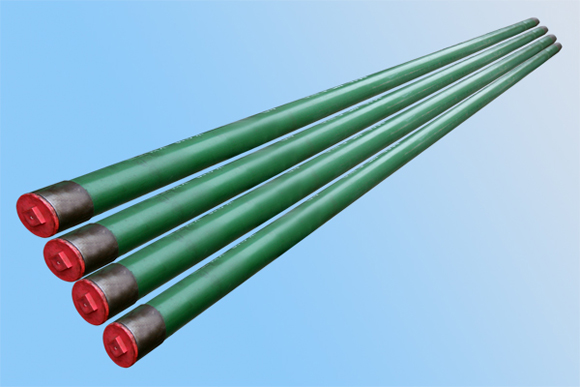

The sucker rod pump is a special reciprocal pump. The power is passed from the ground to down-hole by the pump rod which drives the pump piston doing reciprocate operation.

The sucker rod pump is a special reciprocal pump. The power is passed from the ground to down-hole by the pump rod which drives the pump piston doing reciprocate operation. |

Model |

Code Name

|

Pump dia. mm |

Piston length M |

Pump barrel m |

Tubing Outside dia. Mm |

Pump rod dia. mm |

Extended Connection m |

Applicability

|

|

Tubing |

20/25-106TH |

28.5 |

06~2.1 |

3.3~9.5 |

60.3~73.0 |

15.9~19.1 |

0.6~0.9 |

The oil well which includes salt, sulfur, carbon, dioxide, bacterium, medium and slight sand entry etc. |

|

20/25-125TH |

31.8 |

06~2.1 |

3.3~9.5 |

60.3~73.0 |

15.9~19.1 |

0.6~0.9 |

||

|

20/25-150TH |

38.1 |

06~2.1 |

3.3~9.5 |

60.3~73.0 |

19.1 |

0.6~0.9 |

||

|

20/25-175TH |

44.5 |

06~2.1 |

3.3~9.5 |

60.3~73.0 |

19.1 |

0.6~0.9 |

||

|

25-200TH |

50.8 |

06~2.1 |

3.3~9.5 |

73.0 |

19.1 |

0.6~0.9 |

||

|

25-225TH |

57.2 |

06~2.1 |

3.3~9.5 |

73.0 |

19.1 |

0.6~0.9 |

||

|

30-275TH |

69.9 |

06~2.1 |

3.3~9.5 |

88.9 |

22.2 |

0.6~0.9 |

||

|

40-375TH |

95.3 |

06~2.1 |

3.3~9.5 |

114.3 |

25.4 |

0.6~0.9 |

||

|

40-375TH |

95.3 |

06~2.1 |

3.3~9.5 |

114.3 |

25.4 |

0.6~0.9 |

||

|

Rod pump |

20-125RH/W |

31.8 |

06~2.1 |

3.3~9.5 |

60.3 |

19.1 |

0.6~0.9 |

|

|

25-150RH/W |

38.1 |

06~2.1 |

3.3~9.5 |

73.0 |

19.1 |

0.6~0.9 |

||

|

25-175RH/W |

44.5 |

06~2.1 |

3.3~9.5 |

73.0 |

19.1 |

0.6~0.9 |

||

|

25-200RH/W |

50.8 |

06~2.1 |

3.3~9.5 |

73.0 |

19.1 |

0.6~0.9 |

||

|

30-225RH/W |

57.2 |

06~2.1 |

3.3~9.5 |

88.9 |

19.1 |

0.6~0.9 |

Our special sucker rod pumps can be applied for exploiting various types of wells effectively, such as wells with sand, gas, and high viscosity oil, slant wells, slicing wells, tubingless wells and so on. They have been used in many oilfields and received good results and feedbacks.

Our special sucker rod pumps can be applied for exploiting various types of wells effectively, such as wells with sand, gas, and high viscosity oil, slant wells, slicing wells, tubingless wells and so on. They have been used in many oilfields and received good results and feedbacks.

1. The length of the electroplating pump barrel can be up to 9 m and other parts including rods and tubes can be up to 10 m by using performance of closed loop barrel plating and horizontal deep hole honing, which is environmental friendly;

2. All kinds of plungers are made of stainless steel, electroplating or Ni-P-spray-welding processes;

3. All series of valve balls and seats are made of stainless steel, ceramic, carbide etc.

You may also like

Pumping Unit Coiled Tubing Unit Workover Sucker Rod