English|Русский

|Site map

English|Русский

|Site map

It is widely used for well testing, hydraulic fracturing clean-up and coil tubing or snubbing workover.

The steam heat exchanger is the direct steam heat exchange equipment primarily used for raising the temperature of oil-gas-water three-phase mixture from an oil well to ensure the three phase testing separator to work under the normal temperature.

The work principle is the steam gas from the steam generator directly enters into the shell of the heat exchanger with the help of pressure and heats up the coil directly and thus the media in the coil was heated up indirectly.

The coil is divided into two sections, the upstream and downstream sections, in between is an adjustable nozzle for adjusting the flow rate of the fluid in the downstream coil so as to realize more sufficient heat exchange.

The role of surge tank is to confirm a separator’s oil flow meters data and measure the production of oil. When it is used to wash well without using a separator or a burner, we can safely choke of the low pressure gas to a safe area.

The role of surge tank is to confirm a separator’s oil flow meters data and measure the production of oil. When it is used to wash well without using a separator or a burner, we can safely choke of the low pressure gas to a safe area.

The role of measuring tank is measuring oil, water discharged from the separator.

Oil can be directly injected into the measuring tank. According to level measurement feet and liquid face, the oil-water production can be measured well.

Since the Measuring tank is attached a crude-oil transfer pump, it is convenient to load and transport oil and water.

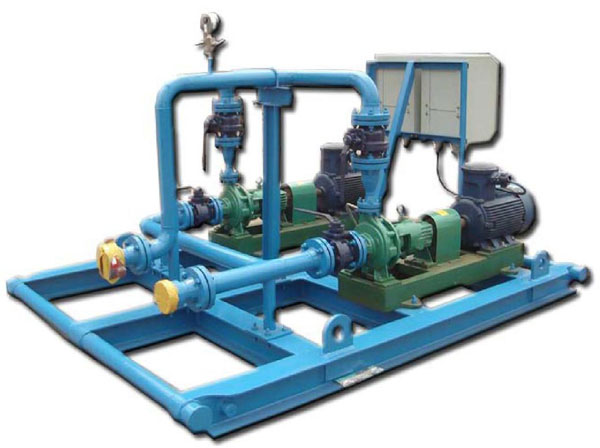

Two sets of centrifugal oil transfer pumps are mounted on the crude-oil transfer pump skid. One is in operation and the other is stand-by.

An explosion proof operating pole and a relevant valve manifold are configured.

A union connection is adopted. The whole equipment will be supplied in a complete skid.

The chemical injection pump injects chemicals into various sets of chemical equipments.

The chemical injection pump injects chemicals into various sets of chemical equipments.

You may also like