English|Русский

|Site map

English|Русский

|Site map

1, Mixer and Granulator

Main Features:

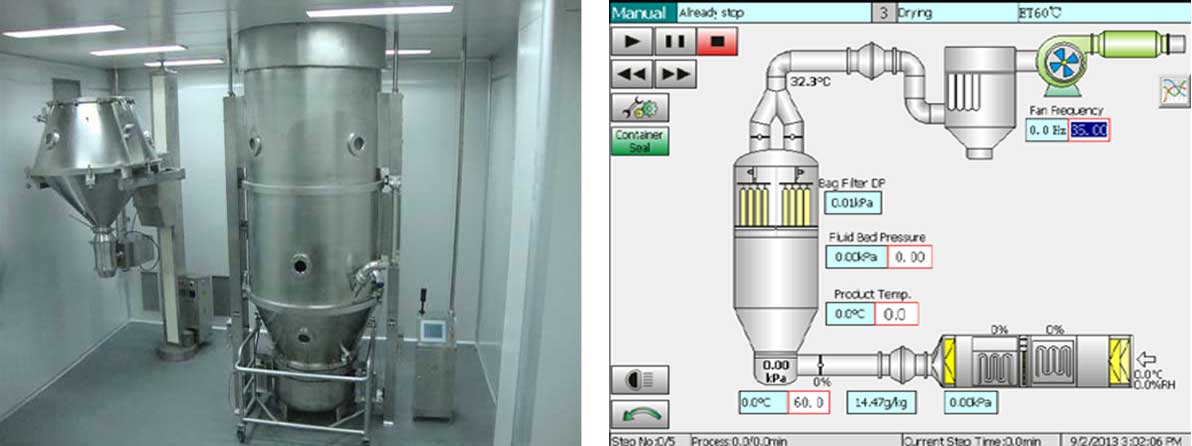

2, Fluid-Bed Production Unit

Granulation Coating pellet, Boiling Granulation, Lab Granulation Coating Pellet. TR’s series Fluid-bed Processors are design and produce to match the most specific requirement to end-users.Main Features:

3, TR-DPH 260 Blister Packing Machine

|

Model |

TR-DPH 260 |

|

Max. Speed: |

Alu/Alu 40 punches/min; Alu/PVC 70 punches/min |

|

Max. Output: |

280 blisters/min. (Alu/PVC Blister size 57-80mm) |

|

Max. Forming Area: |

245x152mm |

|

Max. Forming Depth: |

12mm |

|

Material: |

Max. Width 260mm |

|

Machine Power: |

9.6kW |

|

Machine Dimenssion: |

4 Stations: 2400x740x1700mm 5 Stations: 4450x740x1700mm |

|

Machine Weight: |

4 Stations: 1,800kg; 5 Stations: 1,950kg |

4, Automatic Capsule Filling Machine

|

Model |

NJP3200 |

NJP2200 |

NJP1200 |

|

No. of die orifice |

23(Double) |

19(Double) |

9 |

|

Max Output(capsules/h) |

192,000 |

132,000 |

72,000 |

|

Vacuum |

110m3/h -0.08-0.04Mpa |

110m3/h -0.08-0.04Mpa |

27m3/h -0.02-0.08Mpa |

|

Capsules number |

00-5# |

00-5# |

00-5# |

|

Filling percentage |

≥ 99% |

≥ 99% |

≥ 99% |

|

Filling difference |

<±3 |

<±3 |

<±3 |

|

Idle load noise db(A) |

< 73 |

< 73 |

< 73 |

|

Power |

380V 50Hz 6KW |

380V 50Hz 5KW |

380V 50Hz 3KW |

|

Size L*W*H (mm) |

1420x1180x2150 |

1200x1070x2100 |

800x750x1950 |

|

Weight (kg) |

2000 |

1500 |

850 |

5, TR High Speed Double Layer Tablet Press Machine

|

Model |

TRS-45 |

TRS-55 |

TRS-69 |

TRS-75 |

|

Punch & die type(EU) |

D |

B |

BB |

BB |

|

Number of Press Station |

45 |

55 |

69 |

75 |

|

Max Tablet Diameter (mm) |

25 |

16 |

13 |

13 |

|

Max abnormal prolate axis size(mm) |

25 |

18 |

16 |

16 |

|

Max Output (Tablet/h) |

390,000 |

470,000 |

580,000 |

630,000 |

|

Max Filling Depth (mm) |

20 |

18 |

18 |

18 |

|

Max main pressure(KN) |

100 |

100 |

100 |

100 |

|

Max Pre-pressure (KN) |

20 |

20 |

20 |

20 |

|

Idle load noise dB(A) |

<75 |

|||

|

Power |

380V 50HZ 10.5-13KW |

|||

|

Size L x W x H (mm) |

1260×1260×1950 |

|||

|

Weight (kg) |

3750 |

|||

6, TR-DPH 260A Blister Packing Machine

|

Model |

TR-DPH 260A |

|

Max. Speed: |

Alu/Alu 100 punches/min; Alu/PVC 200 punches/min |

|

Max. Output: |

800 blisters/min. (Alu/PVC Blister size 57-80mm) |

|

Max. Forming Area: |

245x180mm |

|

Max. Forming Depth: |

12mm |

|

Material: |

Max. Width 260mm |

|

Machine Power: |

15kW |

|

Machine Dimension: |

4800x1250x2000mm |

|

Machine Weight: |

2500kg |

7, Electric Tablet/Capsule Counting Machine

|

Model |

Electric Tablet/Capsule Counting Machine |

|

Max. Capacity: |

7500pcs/min for Dia 5mm Tablet Max. |

|

Size of Capsule |

#000-#5 Capsule |

|

Size of Tablet |

Dia 23mm Max. |

|

Size of Bottle |

15-500ml |

|

Voltage |

AC 220V, Single Phase, 50/60Hz |

|

Power |

600W |

|

Air Consumption |

0.05 m3/min |

|

Hopper Volume |

30ltrs |

|

Overall Dimension |

1300x1500x1900mm |

|

Weight |

280kg |

8, Aluminum Foil Sealing Machine

|

Model |

TR-2000 |

|

Sealing Diameter |

20-75mm |

|

Speed |

0-200 bottles/minute (Depending on the diameter of the bottle) |

|

Electrical Requirements |

220V50Hz |

|

Power |

2.5KW |

|

Output Power |

80kW |

|

Weight |

Sealer: 5kg, Conveyor: 40kg |

|

Dimension |

Sealer: 815mm*900mm*1217mm Conveyor: 1800mm*445mm*835mm |

|

Cooling System |

Circulating Water |

9, Automatic Cartoner

|

Item |

Specification |

|

Max. Output |

120 cartons/min. |

|

Range of Carton Size |

Max.150x115x50mm Min.55x30x15mm |

|

Machine Power |

1.8kw |

|

Machine Dimension |

3500x1500x1800mm |

|

Machine Weight |

1200kg |

10, Automatic Palletizing Line (Carton Erector, Carton Filling, Carton Sealing, Pelletizing etc.)